Are you looking for a piece of equipment that will manufacture fertilizer easily and quickly? A circular pelleting facility can provide exceptional efficiency at a low cost. Furthermore, you could possibly create a number of fertilizers using the same machine.

Its primary function is usually to granulate and compress powder fertilizer into fine pellets and contains a very high granulation rate as much as 95%. In reality, when compared with practically every fertilizer granulation machine, like the rotary granulator, double roller extrusion granulator machine, and organic fertilizer pellet mill, its granulation rate is higher. Keep reading to find out the way it operates:

What exactly is a Pan Granulator and How Can It Work?

Granulation is the process of combining many particles or grains, usually using a binding agent and mechanical force also. A pan granulator, often known as a pan pelletizer, is round disc-like equipment that produces fertilizer granules on the pedestal. It really is unique among granulating machines in this it is among the best-suited machines for pelleting using the highest pelleting ratio.

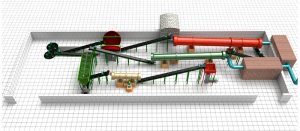

Both organic and compound fertilizer powders can be pelletized with it. It can be used to help make organic fertilizer granules in addition to compound fertilizer granules. Furthermore, it needs some additional auxiliary equipment for efficiency. Considering this, to create a highly efficient fertilizer, combine the pan pelletizer with many other fertilizer-making devices like a compost fertilizer machine, a crusher, a mixer, along with a dryer.

Types of Pan Granulators

• NPK compound fertilizer granulation machines

• Disk pan granulators

• Laboratory disc granulators

• Organic fertilizer plate pelletizers

• Disc pan wet granulation machines

Learning to make Granules When Utilizing Pan Granulator?

A fertilizer granulator of disc kind, unlike an organic fertilizer granulator, is suitable for compound NPK fertilizer production and also organic fertilizer production. For compound fertilizers, you can use nitrogen, potassium and phosphorus sources. Some phosphorus sources include dicalcium and diammonium phosphate.

Potassium sources include potassium chloride and potassium sulphate and nitrogen sources include urea, ammonium chloride, ammonium sulphate and the like. In terms of organic fertilizer, you may use different kinds of raw materials like chicken poo, cow dung, and sheep manure.

Whichever the raw material, the making pellets machine of plate type reduces powders into pellets by usage of centrifugal force. Now for the process, begin by inserting the types of materials in to the machine’s inlet with the top after which the granulating disk will rotate. For the reason that materials can be seen spinning in the disk, be sure you spray enough water to counteract the granules’ effect.

As a result of centrifugal force, friction, and gravity, the type of material will rapidly become pellets. The scraper is used to scrape off any agglomerations that have formed in the disk’s surface. This makes sure that each of the components are equally granulated, giving the pellet a beautiful appearance. Once the pellets are already formed, they will likely exit throughout the outlets for collections as well as any substandard pellets will probably be re-granulated.

Wind Up

With out a pan granulator machine, a fertilizer production line will be incomplete. Moreover, the most efficient way to handle animal manure is to granulate it into organic fertilizer. Contact us for such efficient machines!If you are interested in our machine, you can click on online customer service for detailed consultation.