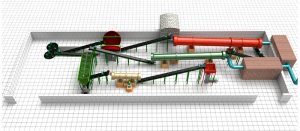

Turning your compost pile is an important part of developing healthy soil, but turning waste into compost can be a cumbersome job. You may make this task easier by investing an a self-propelled making compost turner. These kinds of machine does every one of the hard be right for you, so you won’t should do anything but feed your raw material into it and watch over it even though it operates.

Are you aware, however, there are factors which affect the composting rate of self-propelled compost turners? In this posting, we’ll explore the principle reasons why your composting rate could possibly be slowing down and what to do to get it back in line.

The composting rate from the self-walking kind of fermenting machine declines under the influence of several factors including temperature, humidity, moisture content, carbon-nitrogen ratio, oxygen content, aeration interaction, pH value and particle size. Let’s take a closer look at each of these factors, in order for anyone to obtain a better comprehension of the composting process and also the actions you can take to increase the composting rate of your respective self-propelled compost turner.

The temperature is among the factors that happen to be beyond the control, so there’s not a whole lot you could do about this. However, you are able to adjust the compost turning parameters of your respective machine, to guarantee a slow decomposition rate and a long fermentation process.

The carbon-nitrogen ratio can be something will your advantage with regards to creating high-quality compost to fertilize your crops with. You have to know that different materials have different carbon-nitrogen ratios. For the best results, you might like to process materials who have similar C:N ratios. For instance, cow manure includes a C:N ratio of 20:01, nearly the same as normally the one of coffee grounds. This means you can safely mix both materials to get high-quality compost by using a self-propelled compost turner. Similarly, bark and sawdust have very similar C:N ratio. Before you start your composting process, you must be sure you do learn how to combine these materials for the maximum of effect.

Moisture is an additional thing that influences the composting rate of self-pushed compost machine. The role of moisture would be to promote the absorption of nutrients by microorganism. Ideally, composting raw materials must have a 50% to 60% water content. Too low moisture will make organic matter tough to decompose, as it would slow down the microorganism activity. The outcome would be a slowing down from the composting speed, ultimately causing anaerobe decomposition. Your compost would stink and it could be lower in nutrients. Remember that the moisture of the composting material is tightly linked to the ventilation capacity of your respective machine.

Among the factors worth paying close attention to will be the particle size of composting raw material. Lowering the dimensions of the pellets can help enhancing the surface part of the granules, and therefore increase the composting speed by intensifying the action of microorganism.

Your main goal ought to be to obtain stable and mature compost that doesn’t cause negative effects on humans. For this reason you must do your greatest to manage the composting process as closely as you possibly can.