In the fermentation equipment, the poultry manure turning machine is now more popular in the market. The overall operation is simple, and the cost is relatively cheap. There are many types of stacker turning machines. Different materials can be selected for different materials. There are many types of materials. Sometimes we may The materials need to be adjusted, but our equipment and site cannot be adjusted casually, so we must consider the adjustment of the later raw materials when selecting the equipment.

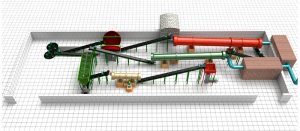

The chain-plate type stacker for poultry manure is composed of a combination of multiple components and multiple structures. The chain-plate type stacker is a working equipment erected on the upper part of the fermentation tank and supported by rails laid on the fermentation tank. It consists of a moving frame and a stacker trolley. The moving frame part is welded by large H steel, and the bottom is equipped with walking wheels, which can be easily moved left and right. The most common parts of the stacker are the trolley part, such as power, discharge, stacking, forward and backward movement, hydraulic pressure, limit, operation computer and so on.

Power: The overall maximum power output of the trolley is driven by a 22KW motor, which is mainly used for turning the chain plate. The chain plate part is composed of nearly a thousand wear-resistant blades, which can effectively turn the material evenly.

Discharge: The biggest advantage of the chain poultry manure compost turner is that it has its own discharging function. This function can save nearly 70% of the overall consumption of labor and mechanical equipment. This function uses the chain to transport materials to the discharging part, and then The material board sends the material to the conveyor, and the conveyor sends the material to the production granulation workshop, saving 2-3 workers and forklifts in the middle.

Movement: The overall working mode of the chain poultry manure composting making machine is carried out by the movement of the overall frame, and the movement of the overall frame is carried out by four sets of motors driving the walking wheels.

Hydraulic: The lifting work of the chain plate is all provided by the hydraulic system, and the lifting force is provided by double hydraulic rods to complete.

Computer system: The overall control system, the operation of the poulty manure fermenting equipment is all controlled by the computer, to achieve precise control, every action can be executed perfectly, and the overall control is operated by a remote control, which allows us to greatly save manpower when working. The input of the computer-controlled equipment operation can be more specific to every action of the equipment.

The PLC intelligent chain-plate stacker is the most versatile stacker among current stackers, and it is also more popular in the market and the future trend. Reducing labor input can reduce overall consumption.When you have any purchase intention, please connect with us as soon as possible.

https://www.fertilizerfactorymachine.com/poultry-manure-to-compost/